Product Categories

A comprehensive range of high-performance industrial air pollution control systems and spare parts, engineered for optimal efficiency and long-term reliability.

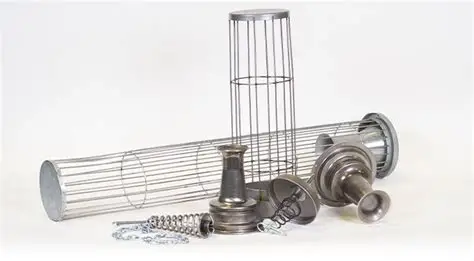

Bag House Components

A Bag House (also known as a Fabric Filter or Bag Filter) is an industrial air pollution control device designed to remove particulates (dust, fly ash, and other fine particles) from process gas streams. It works on the principle of filtration – dirty gas passes through fabric filter bags that trap dust particles on their surface, while clean air exits the system.

Know More...

Filter Bags are the heart of any baghouse dust collection system. They are fabric tubes or envelopes made of specialized filter media designed to capture dust particles while allowing clean air or gas to pass through.

Cages are the supporting structures inside a baghouse that hold the filter bags upright and prevent them from collapsing during operation. They play a crucial role in maintaining proper airflow and maximizing the efficiency and service life of filter bags.

The Pulse Jet System is the most widely used bag cleaning mechanism in modern baghouses. It ensures that filter bags remain clean, allowing continuous operation and high dust collection efficiency. The Solenoid Valves are the key actuating components that control the compressed air flow used for cleaning.

A Hopper is the conical or pyramidal-shaped bottom section of a baghouse, ESP, or other dust collection system where the dislodged dust and particulate matter accumulate before being discharged. It is a critical component for maintaining proper dust flow and avoiding re-entrainment into the clean gas stream.

An alternative cleaning method where reverse airflow is used instead of compressed air pulses

ESP Spares

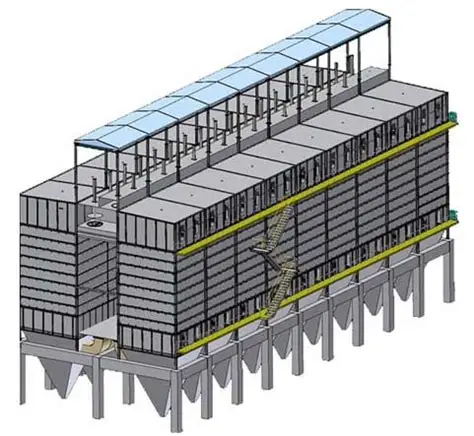

An Electrostatic Precipitator (ESP) is an advanced air pollution control device designed to remove particulate matter, such as dust, ash, and other fine solid particles, from industrial flue gases. It is widely used in industries that produce high volumes of exhaust gases, including cement, steel, power generation, chemical, and pulp & paper industries. The ESP is particularly effective in capturing fine particles that are difficult to remove by conventional mechanical filtration methods.

Know More...

Emitting electrodes, also known as discharge electrodes, are a critical component of an Electrostatic Precipitator (ESP). These electrodes play a central role in the efficient removal of fine dust and particulate matter from industrial flue gases. Designed to generate a high-voltage corona discharge, emitting electrodes impart an electrical charge to dust particles suspended in the gas stream, enabling their subsequent collection on the ESP’s collecting plates.

Collecting electrodes, also known as collector plates, are one of the most critical components of an Electrostatic Precipitator (ESP). These electrodes are responsible for capturing and holding the electrically charged dust and particulate matter from industrial flue gases, ensuring efficient gas cleaning and environmental compliance. High-quality collecting electrode spares are essential for maintaining ESP performance and achieving optimal dust removal efficiency.

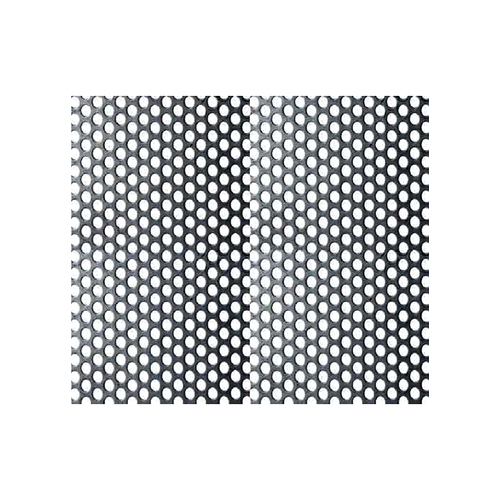

The Gas Distribution Screen (GDS), also known as the gas distribution or perforated screen, is a vital spare part of an Electrostatic Precipitator (ESP). Its primary function is to ensure uniform distribution of flue gas across the ESP’s cross-section, which is critical for achieving high dust collection efficiency and optimal performance of the precipitator.

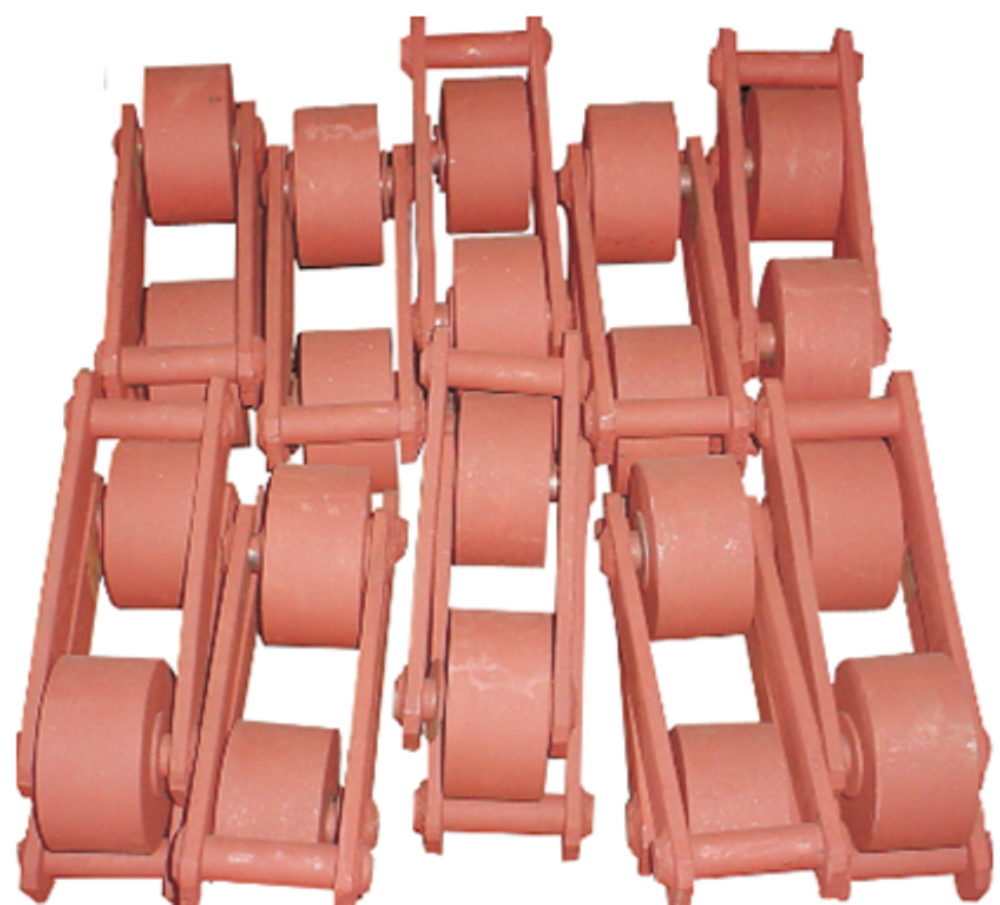

The Hammering System, also known as the Rapping Mechanism, is a crucial spare part of an Electrostatic Precipitator (ESP). Its primary function is to ensure the continuous cleaning of collecting electrodes by dislodging accumulated dust, preventing performance degradation, and maintaining the high efficiency of the ESP in industrial operations.

Ash Handling System Spares

An Ash Handling System (AHS) is an essential component of industrial plants such as thermal power plants, cement plants, biomass plants, and incinerators, designed to collect, transport, and safely dispose of ash generated during combustion processes. The system ensures continuous operation of boilers, prevents environmental pollution, and facilitates efficient handling of large quantities of fly ash and bottom ash.

Know More...

The Dome Valve is a critical spare component of an Ash Handling System (AHS), designed to control the flow of ash from hoppers, silos, or storage bins in industrial plants. t ensures smooth, controlled discharge of ash while maintaining airtight sealing, preventing air leakage, and avoiding dust spillage. Dome valves play a pivotal role in maintaining the efficiency, safety, and reliability of ash handling operations.

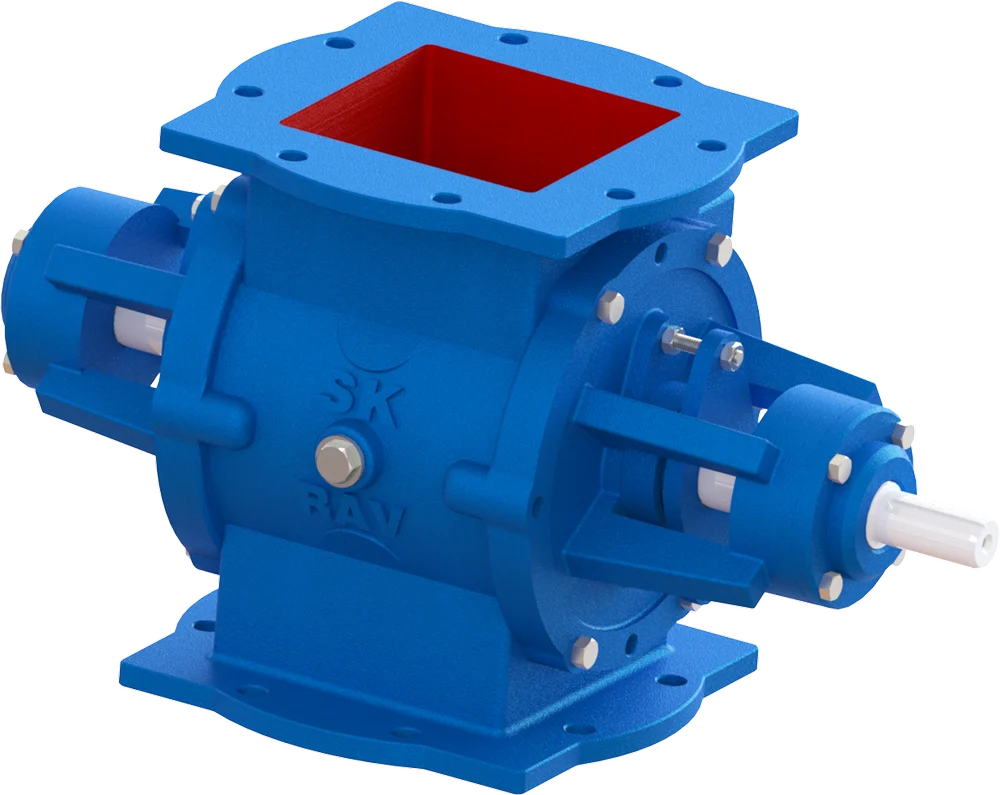

The Rotary Air Valve (RAV) is a critical spare component of an Ash Handling System (AHS), designed to regulate and control the continuous flow of ash from hoppers, silos, or ash collection points to downstream conveyors or pneumatic transport systems. It plays a vital role in ensuring smooth operation of ash handling processes in industrial plants.

The Screw Conveyor is a vital spare component of an Ash Handling System (AHS), designed for the efficient, controlled, and continuous transport of ash from hoppers, silos, or collection points to disposal areas or storage silos. It is widely used in industrial plants to handle both fly ash and bottom ash safely and reliably.

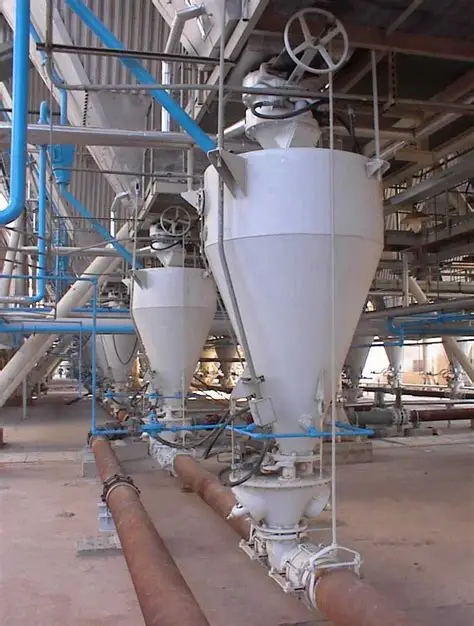

The Pneumatic Conveyor is a crucial spare component of an Ash Handling System (AHS), designed for the efficient, controlled, and dust-free transport of fly ash, bottom ash, and other combustion residues from hoppers, silos, or collection points to storage silos or disposal areas. Pneumatic conveyors are widely used in industrial plants such as due to their flexibility, reliability, and ability to handle abrasive and fine particulate matter over long distances.

Heater Image

The Heater is an essential spare component of an Ash Handling System (AHS), designed to maintain optimal temperature conditions within ash handling equipment and pipelines. In industrial plants. The heater ensures smooth and uninterrupted transport of ash by preventing condensation and freezing, particularly in pneumatic conveyors, rotary air valves (RAVs), and pipelines.

Core Industrial Components

Standalone equipment engineered to deliver reliable airflow control, filtration, pressure management, and vibration absorption across demanding industrial environments.

Know More...

Dampers are critical components used in industrial air handling systems, boilers, ducting, and exhaust systems to regulate the flow of air, gases, or flue gases. They play a vital role in controlling combustion efficiency, maintaining optimal airflow, protecting equipment, and ensuring environmental compliance in industries

Air filters are essential components in industrial ventilation, process systems, and pollution control equipment. They are designed to remove dust, particulate matter, pollutants, and other airborne contaminants from air or flue gas streams. Air filters play a vital role in protecting equipment, maintaining process efficiency, and ensuring clean and safe working environments across industries

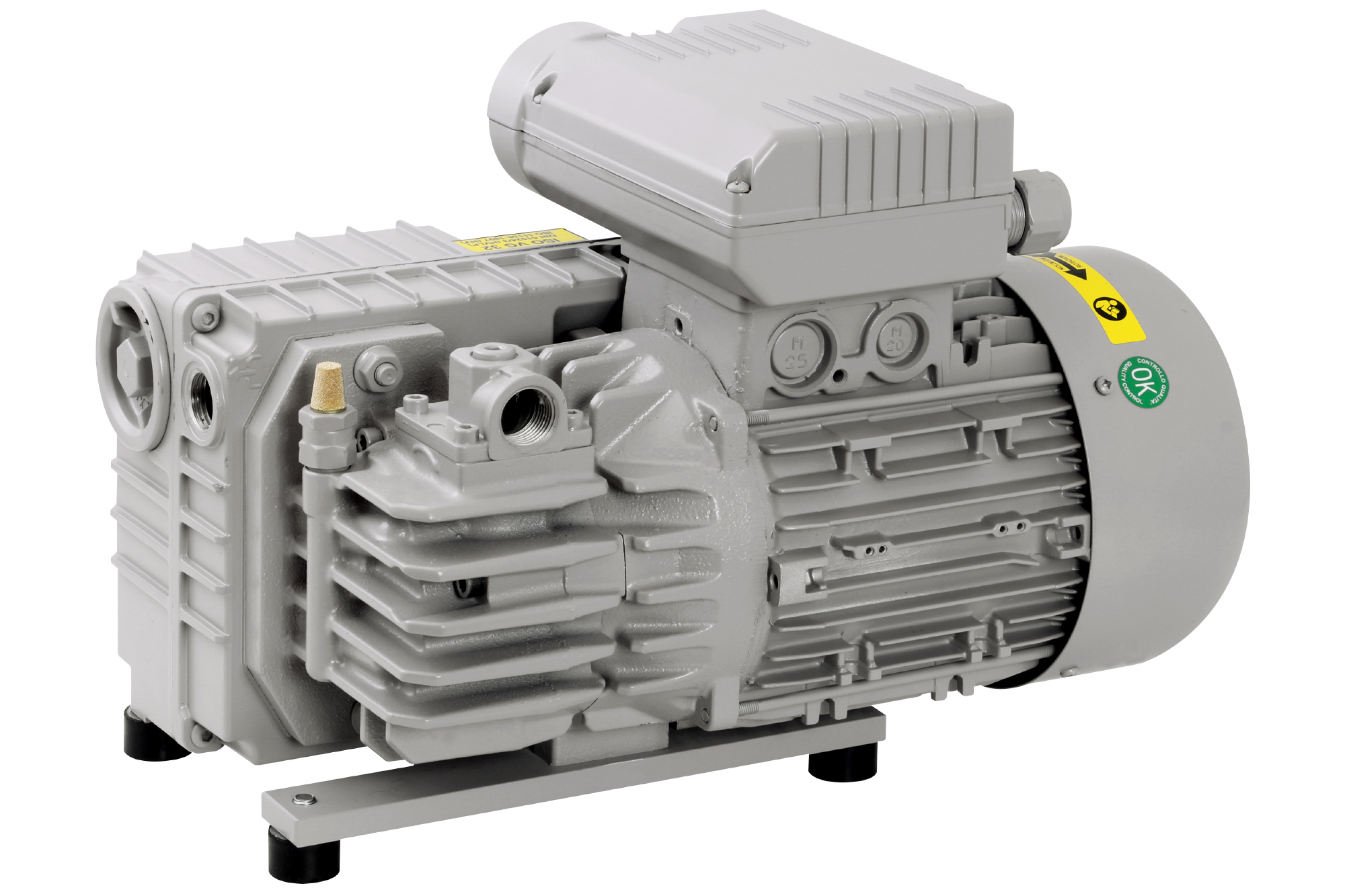

Vacuum pumps are essential components in a wide range of industrial processes, designed to create and maintain a vacuum or negative pressure by removing air, gas, or vapor from a closed system. They are critical for ensuring efficient operation, process reliability, and environmental compliance across industries

Expansion joints are vital components in industrial piping, ducting, and equipment systems, designed to absorb movement, vibration, and stress, thereby ensuring the reliability and longevity of the system. They are indispensable in applications where thermal fluctuations, mechanical forces, or pressure changes occur.